Picture Source: Honeywell

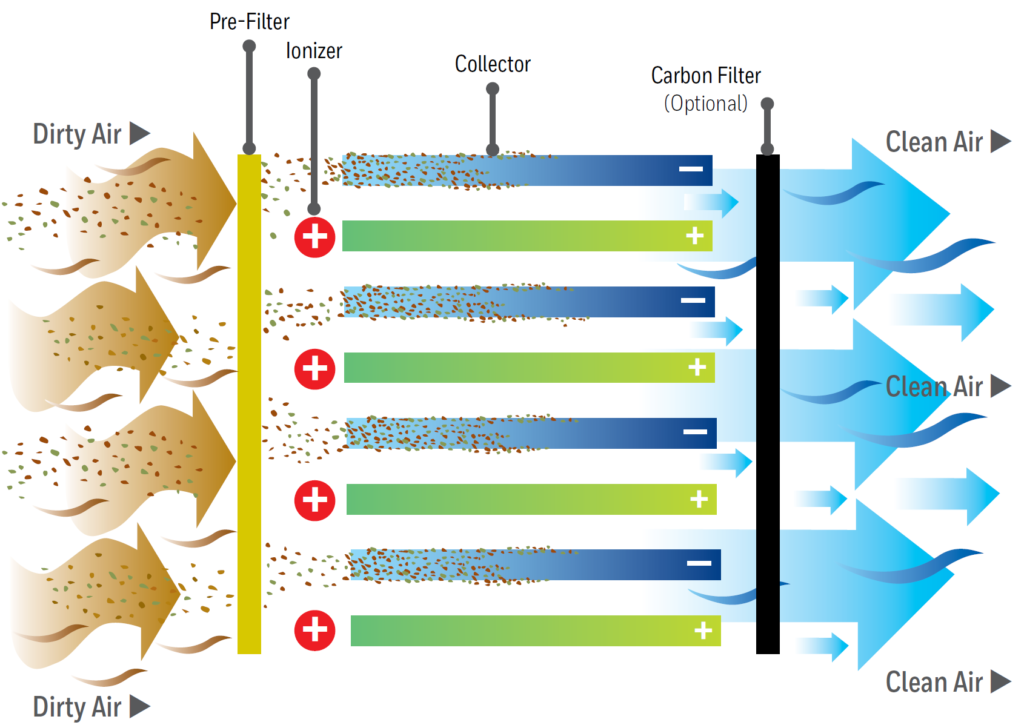

Electronic Air Cleaners (EACs) utilize the principle of ‘electrostatic precipitation’. Air is drawn by the AHU fan blower through a fine washable aluminium mesh pre-filter which traps the larger dust particles and contaminants. The remaining particles which include fine dust, smoke particles, pollens, mould spores and bacteria, some as small as 0.01 micron, pass into a strong electrical field (ionising section) where the particulate receives an electrical charge. The electrical charge is imparted on the microscopic particulates by the strong electrical field created by ionizing wires charged to high voltages of the order of 8,000 volts DC.

The charged dust particles then enter a region filled with closely spaced parallel aluminium plates alternatively charged with positive and negative voltages of the order of 4,000 volts DC. Positive plates repel the positively-charged particles which are attracted by and retained on the negatively-charged plates by electrostatic forces, further supplemented by intermolecular forces, causing the particles to agglomerate. Similarly, the negatively-charged particles are attracted to the positively-charged plates.

Picture Source: Mitsubishi

The net effect is that a lot of very small microscopic particles like smoke and bacteria are efficiently removed without the ‘restraining effect’ of mechanical media filters. Without the high pressure drops experienced in mechanical media filters, the AHU fans can run at a much lower speed while delivering the same amount of air. With a high removal of small sub-micron sized particles, the cooling coils stay cleaner, resulting in better heat transfer and energy savings.